In the Moment of Decision

Words to live by; “In the moment of decision your destiny is formed”. The first time I heard those words I was busy absorbing everything I could from Anthony Robbins at his Date with Destiny seminar in Toronto. Out of all the lessons I have learned in life, you can spin these words anyway you want to and you will always come to the same conclusion. One thing leads to another, and then another and the ultimate outcome came from the initial decision.

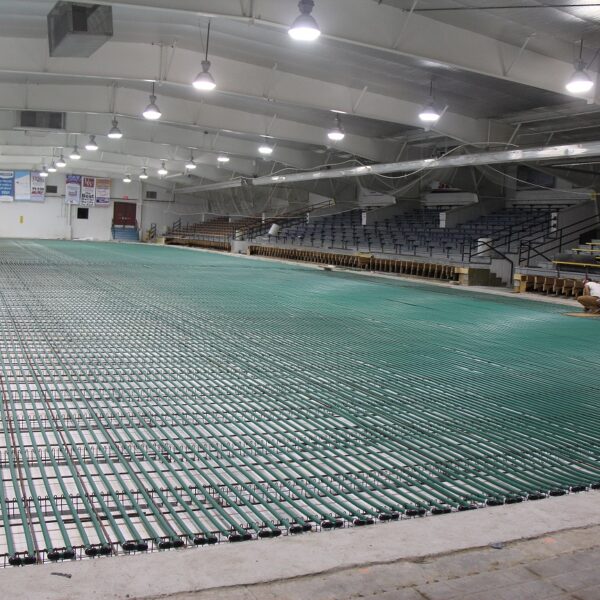

During the week I was on site July 6th through 15th, many things were accomplished, structured and changed. One simple decision of placing the tank outside the building brought on a series of concerns and necessary changes. The second decision to route the piping on the roof instead of side wall at tank height added challenges. My typical approach is to do whatever we can within the project scope and alter as we see fit without having to charge for extras. You do the best you can but simple decisions make big changes to a system originally designed site unseen.

Historically I design a lot of systems with the use of atmospheric water tanks because they are cheap and customizable. I use these tanks in both an insulated and un-insulated state for TES or thermal energy storage, storage and simple capacity. The downfall is the tank cannot be pressurized. So every consideration must be taken to avoid any possible siphon effect occurring within the piping system. You also have to be aware of vapor locking pumps, and the application of an anti-vortex device may be necessary. All to ensure the pump does not create a challenge by virtue of its placement as it tries to do its job.

Both decisions effected project costs. The original design called for tank placement in the mechanical room with the piping running at an exterior elevation no higher than top of tank level. If we needed to raise the tank we would bring in a stand at minimal costs to ensure no siphon effect would occur. Discussions were held and it was decided there was no room for the tank in the mechanical room. So we looked at two parallel adjoining rooms and due to access and egress rules were unable to place the tank indoors. A convenient location was discovered. We only had to make a few minor changes on the interior wall for the new penetrations and pump mount locations, but still changes add time and of course material costs. Plus, the original concept allowed for a short run of 3” pipe interconnecting to an existing warming floor loop for heat dissipation from the tank. Concept also called for use of the existing pump but as noted in a previous post the pump brought no value whatsoever as it was originally undersized, running since inception costing money and adding little or no benefit to in-floor system as designed. From an esthetics point of view it was decided the pipes should run on the roof. No problem in my mind, lets just do it. We have a client waiting for a system install lets make it work and keep the overruns as low as possible so no extras are required. The concept to ensure we avoided any form of siphon would be to install pipes that passed the highest vertical point of the fluid by 1.5’ and then returned to normal levels breaking the siphon potential. It was a simple solution, creating a camel back return and low cost. However the more I thought about and planned for it I was plagued with the “what if scenario”. I always ask “What if” no matter what we are doing or what the client is looking for. In this case it was impossible to know that in a 3” pipe with the pump strength and limited amount of head designed, if the surface tension or contact with the pipe walls would be interrupted in a power failure. All we needed was enough break to allow air space or bubbles to form breaking the siphon potential. As I always like to sleep at night, and with a 30 foot high peak elevation and ground tank at a height of 10 feet, if we could not guarantee the break in contact, we could be facing a siphon drain back to the tank of the entire system. Not a bad thing with a bigger tank. With the tank we had, we would have to balance the backflow and that means we would have to pick a level on the tank that is a not to exceed and trust in others that they will never fill past a given point. Too risky, so we had to add electronic solenoid valves into play. We spoke with the client they understood and agreed and we pushed on. We found the valves as cheaply as possible but now you have to add 110 volt power to the cost and get it to the roof to power the valves. One thing leads to another.

As we circle back to the relocation and placement of the tank outside. We had to install a pad, rent a compactor and buy a plate to support the weight for the 850 gallon tank. Not exceedingly expensive but all extras. Next we have to evaluate the tank insulation. Does it make sense to insulate the tank against mother nature’s infiltration. Considerations of velocity, exchange rate within the tank, downtime, heat of the day etc. Everyone of these elements by itself or in concert with others makes a different determination for the added costs of insulation. The tank is designed to accept temperature change within the system. If the temp rises to high in the tank there is a loss of efficiency within the system so insulation makes sense. Then we consider we are moving fluid in and out of the tank at 250 gpm which tells us as long as we are moving, our temperature transfer is at a very low rate, however the second the pumps are not called to an on position, the tank is vulnerable to temperature gain.

Every step of the way you reflect on, “In the Moment of Decision Your Destiny is formed”.