What About Grocery stores

I was asked by one of my sales guys “I know we do grocery stores, but what can do to help”.

Grocery Store, convenience store, ice rink, retail, hospital, hotel, you name it, they are almost identical in approach once you understand the load profile of each of the facilities. Since I was asked about grocery stores lets take a look at a typical facility. First of all in today’s world, there are many sophisticated and energy wise grocery store operations. A lot of them have energy managers in place paid to do what we do everyday and some of those energy mangers would prefer you don’t call them and tell them what you can do, because they have already looked after everything. My response is always. “great news”, but for my edification would it be possible for me to ask you a few questions? If they have time they are usually congenial and we move on.

What I find is that no matter the sophistication level, there is almost always something we can help them with and the bottom line will come down to payback or ROI. If you can show them a way to save money through technology and it can be justified in terms of return on investment 9 times out of 10 they will jump on board. That does not guarantee you a sale. Remember you are dealing with a savvy energy guy on the other end eager to reduce the OPX of his store or chain. So he may just thank you and show you the door and move on the proposed improvements himself. Not that that is a bad thing, but that is why it is critical to ensure you have an NDA in place or you work with products that have been branded your own like what we have at DSB. It is also critical that any proposal is sent to your supplier to ensure there is no circumvention.

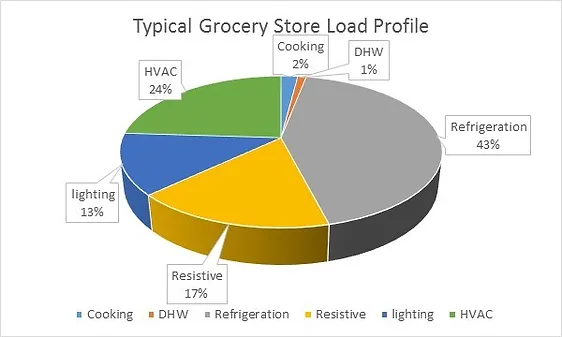

[endif]–Now onto what we find. Grocery store load profiles vary pending the layout of the store, square footage and percentage of produce vs frozen foods. So it is critical you conduct an audit to determine the operating hours f the facility, obtain an active inventory of the equipment in store and possibly set metering in place to fine tune the actual loads of the various components. Nameplate information gives us a pretty solid approach to inventory and then you have operating hours to correlate to the load, but what you don’t have is run time cycle times of the refrigeration equipment and the HVAC. This is critical in the event you are being asked for a guarantee against your savings. But in most cases the client is not willing to spend the funds necessary to setup and monitor the run times and amperage draw of the equipment. This is where we apply our national database of previous studies conducted to determine how the weather and the equipment respond to environmental conditions along with restocking etc. ![endif]–

Now that we understand the Load profile what can we do? Here is a letter I sent to a chain of small grocery stores based on their needs and study.

Re: Energy Conservation

It seems like today there are so many options and so many players in energy conservation it is difficult to determine what is the best approach for any party in any arena to take.

DSB Management And Associates has been in energy conservation for the past 30 years. We strive to bring the cutting edge technology to the market and those that have evolved with us. Our skill set is diverse and functional in every vertical market. We are a turn key solution provider that identifies the issue relative to each facilities unique load and apply FIMS or facility improvement measures to meet the needs of the client. For 30 years we guaranteed our results and now in todays environment we offer the same services but guarantees bear little credence because the technology itself offers the intelligence to get the job done.

With knowledge of the typical store in mind there are several technologies that can drive the client the savings model to appeal to the ROI requirements of the client.

Load distribution determines savings. In order to compile true projected savings an audit or O&M list needs to be compiled. However, assuming we use a typical load distribution we know that the majority of the load and consumption in a GStore setting is comprised of Lighting, HVAC, Refrigeration, and Resistive load. We will also assume you have taken care of the low hanging fruit like lighting; store, exterior and case. Which essentially leaves HVAC and refrigeration. Two completely different sources of demand yet the largest consumers and systems that can benefit from each other’s unique consumption of energy. Without any question savings in these two areas can yield between 20 and 35% savings of the respective load and therefore offer significant savings through the application of smart technologies as demonstrated in the flowing pages.

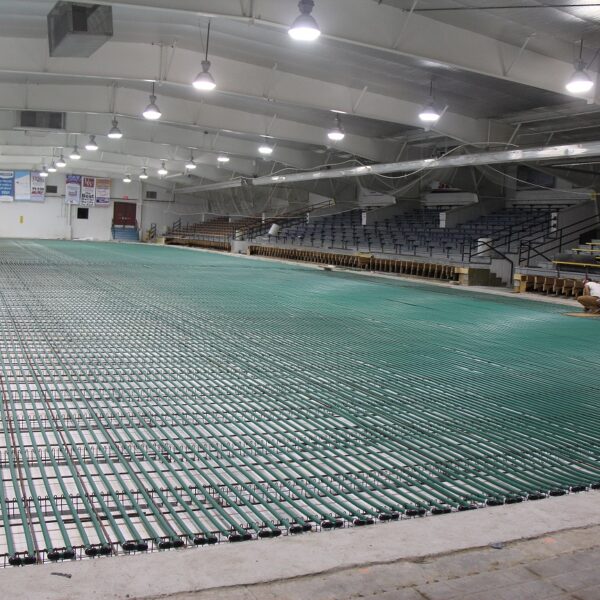

When we evaluate HVAC and refrigeration in a preconstruction or upgrade scenario for a GStore application, we must consider; the HEAT SUPPLY- RTU or slab mounted furnaces for Interior heating comfort can purchased and applied from the lowest commercial efficiency of 80% up to 97 percent. That tells us for every dollar spent we receive a maximum of .97 energy units. For AIR CONDITIONING – The energy efficient ratio (EER) of the air conditioning system should be the highest available and at least EER 13.9 (seasonal EER 13 or better). Air conditioners should be equipped with economizers to take advantage of natural cooling when outdoor air temperatures permit. SLAB HEATER CONTROLS – Some stores utilize in-slab heaters for snow and ice melting on sidewalks or around car wash areas. In most cases, these systems are turned on seasonally and heat the slab when temperatures are below freezing. Controls are now available that allow the system to provide heat only when snow or ice is actually present, and significant savings can be achieved. Then we should consider in slab radiant heat as an option which lends itself to GEOTHERMAL Comfort and Refrigeration. A ground source heat pump, or energy loop, is an ideal system in a building in which there is both heating and cooling. A grocery store could benefit from a geothermal system since space heating and cooling, refrigeration, and water heating and infloor heat and or cool can all occur simultaneously through a Geothermal system. In this type of system loop, heat rejected from the refrigeration system is added to the energy loop and can either be harvested immediately by other appliances or stored for use later in the year. Another advantage of energy loop systems is that they require smaller compressors on the refrigeration system since liquid cooling is more efficient than with conventional air cooled compressors. By being able to integrate the heating and cooling systems into one system, high energy cost savings can be realized. The highest SEER ratings of 34 go to geothermal heat pump systems and generate a 4:1 ratio, so for every dollar you spend you can realize up to 4 energy units, instead of .97 as listed above in conventional HVAC .

Modelling grocery stores is pretty straight forward and depending on location the input values vary as do the load profiles and equipment from store to store. Having said that we have completed an enterprise model for XXXXXXXX making several assumptions that will follow the FIMS outline listed here;

DSB is essentially brand neutral and focuses on FIMs that make a positive impact on the load portions treated for conservation and demand side management. We further complete analysis for alternative energy supply coupled with emergency power solutions and Demand Response to optimize the rates and incentives offered by the various utilities. This may include rate change and aggregation of loads to maximize savings for our clients.

FIMS By Load %

Refrigeration – 55%

HVAC 25-30%

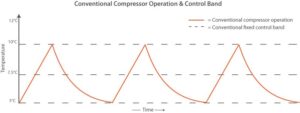

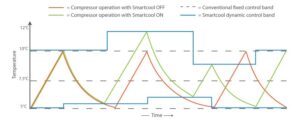

Smartcool’s ECO3 and ESM use intelligent compressor optimization to save an average 15% kWh and give customers a payback in 12 to 36 months. Air conditioning, refrigeration and heat pump (HVAC-R) units waste a lot of energy through natural inefficiency. Their compressors consume about 70% of the total energy used by the system. The average building has about 35% of its total energy used up by these systems- and many businesses see much more of their energy bill coming from their cooling systems. The ECO3 or ESM are secondary non intrusive systems that are installed between the thermostat or primary controller and the compressor in any HVAC-R system. Here’s how it works:

Conventional Cooling

SCADA offering unique Refrigeration and HVAC algorithms. Full SCADA operations allow us to know when each and every element of electrical consumption and demand is in operation in real time. The system is designed to learn and understand the operational requirements of the various comfort and refrigeration equipment and determine an algorithm that optimizes performance and is the direct first line of defense in energy conservation. It enables the customer to participate in Demand Response opt in programs where the utility pays for the demand reduced in the event they need to cut back production. This is a lucrative add in for any energy manager. Some of the Screen shots provided in our SCADA system designed by Winn Energy Controls of San Diego are as follows. Typical savings realized throughout the SCADA operations are 35% of the affected load.

Run time, load and meter information is supplied in real time and is stored on board for up to one year. All data is uploaded in 15 minute intervals to match that of utility billing systems. Control and set points can be adjusted and monitored from any electronic device with Wi-Fi Access. All units communicate via 4G wireless networks and over Lan connections. All reporting is California compliant for measurement and verification purposes. Reports are customizable and can be downloaded printed or viewed on screen.

Capacity includes: Lighting Controls by circuit, Analog in and out for sensors, temp pressure humidity etc., HVAC control for any form of comfort system, Generator control, Sub meter for up to 3 meters, 8 digital relays for on off.

Screen Shots: